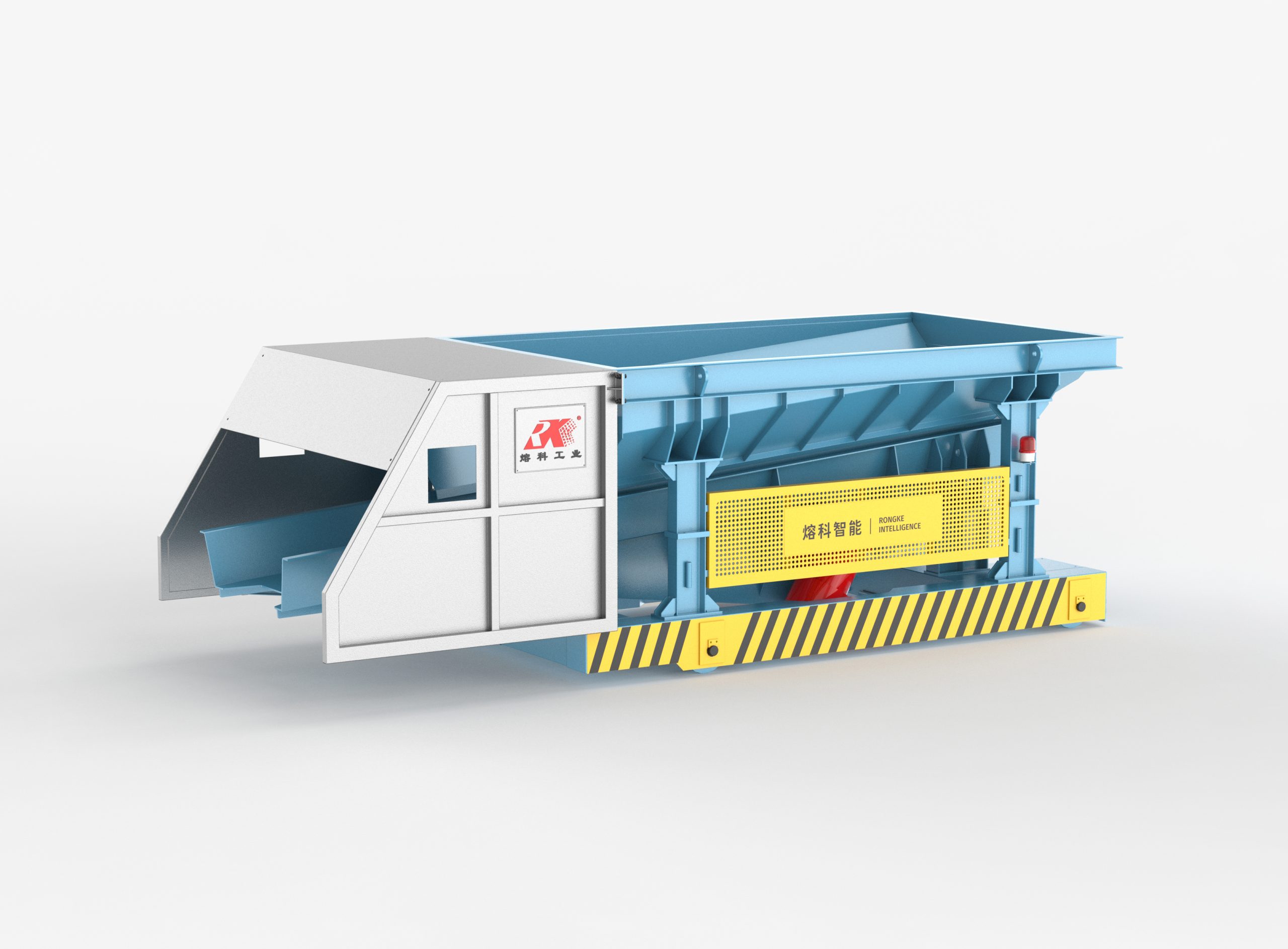

Intermediate Frequency Coreless Induction Furnace

Advantages:

- 1. Noise is 30% lower than similar products;

- 2. The furnace shell adopts a fully enclosed furnace shell, which effectively avoids coil ignition caused by dust pollution;

- 3. Since the closed furnace shell provides secondary shielding for the magnetic field of the coil, the amount of magnetic radiation generated by the equipment is equivalent to 10% of similar products, which is far lower than the national standard.

Product Description

Intermediate Frequency Coreless Induction Furnace

The Intermediate Frequency Coreless Induction Furnace body is endowed with more interactive windows, combined with more quality details and a higher level of technology. Not only the material, processing technology but also craft are at the leading level in the industry, further ensuring that production is safer, more stable and more energy efficient.

IDE furnace leakage alarm system, safe and reliable, patented design, EU CE safety system certification

Rongke IDE full-time and all-round furnace leakage alarm system

Leakage detection principle: Molten iron seeps from the gap of the furmace lining, and the leakage current alarm is triggered when it contacts the current detection electrode; if it penetrates to the coil, the voltage detection circuit would sound alarms and indicate the specific location.

Grounding alarm detection principle: When the molten iron penetrates 2cm away from the coil, the leakage current of components to the ground is greater than the set value, or the conductivity of the coolant is higher than the set, the intelligent system will sense and trigger the alarm.

Leading energy saving and repeatedly pioneering

The coil is the heart of the furnace. Rongke uses the TU1 grade oxygen-free copper of Chinalco luoyang Copper Co., Ltd as the raw material and the thickest wall copper tube in the industry made by cold extrusion process. Combined with double coil technology, achieving More energy efficient products.

Magnet yoke technology

Magnet yoke is made by high-quality cold rolling directional silicon steel sheets. Magnetic loss is less than 105 and the coverage rate of magnet yoke is higher than 70%. Magnet yoke support the induction coil from every direction and gathers the induced magnetic field to the molten bath.

Water flows through both sides of the magnet yoke, which makes the heat dissipation balanced and effectively improves the working life.

Magnet yoke combines the cooling function with supporting functions, which is maintenance-free.

The use of premium silicon steel sheets and the first-class design contribute to the low magnetic loss, small heat productivity and long working life.

Strong supporting system stable and worry-free

| Tilting furnace drive system | Cooling system | 360 Type dust hood |

| The hydraulic oil pump has one use and one standby. All oilcylinders have explosion-proof valves and protective covers, and the exposed oil pipes are equipped with fire-proof sleeves. | All are cooled by enclosed distilled water, all waterways are equipped with water temperature and pressure monitoring, and German Continental brand carbon-free rubber pipes are used. The cooling system is linked with the leakage alarm. | Driven by double hydraulic rods, stable and not flutter, multi-directionalopening and closing, strong suction. |

Attention to detail and strict quality control

From design concept to production, Rongke’s overall production process has strict related production requirements and inspection standards, so we will treat every detail rigorously, so that customers feel Rongke’sfirst-class quality…

Ingenious first-class quality: Intermediate Frequency Coreless Induction Furnace

Fully enclosed design steel furnace shell design, heavy-duty strength furnace body manufactured in accordance with international standards, higher integrated strength, so in the welding process, the most advanced welding technology is used to achieve fully enclosed, powder prevention and low magnetic radiation, And safety and reliability, good rigidity, low noise, easy maintenance and other advantages.