Automatic Pouring System

Advantages:

- Safety: workers entirely separated from molten; automatic safety system

- Economic: vision system control, accurately pouring control; prevent over pouring and lack pouring

- High Efficiency: as fast as 600 moulds/H; saving pouring human labor

- Higher yielding rate: temperature holding accurately, ensure pouring quality; pouring speed control accurately, less defection rate

Product Description

Why choose Automatic Pouring System?

In the fierce competition, everyone is pursuing higher efficiency, better quality and quicker rhythm. For foundry enterprise, how to pour faster with better accuracy and safety is an unavoidable topic. Traditional pouring, either by tundish or semi manipulator or manual scoop, some problem is inevitable: 1. a lot of human labor needed; 2. not accurate enough, molten waste oftenly; 3. pouring temperature is not ensured, causing more defecting rate; The demand for Automatic Pouring System grows higher and higher.

Rongke Automatic Pouring System: Smarter, Better Accuracy, More Reliable

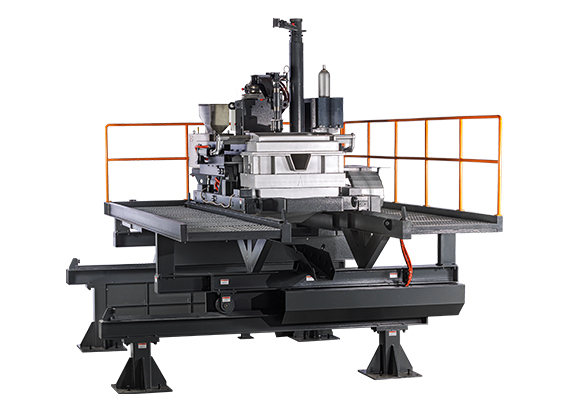

● Bottom type un-heated pour machine

Scope of application

The pouring machine has removable module heavy duty ladle with good insulation effect, specially suitable for grey iron, ductile iron, vermicular graphite cast iron foundry or production need switch between different alloy. This pouring machine is convenient to tilt and maintenance, nozzle changing, feeding and pouring can be operating simultaneously. Self-developed vision align system along with high-end PLC control system and servo-driven stopper rod enable the system a sensitive, reliable and economic features.

Advantages

- Patented pouring ladle design

- Automatic liquid level compensation

- Low energy consumption and easy maintenance

Specification

| Model | RKJ0.75 | RKJ1.0 | RKJ1.5 | RKJ2.0 | RKJ3.0 |

| Rated Capacity (KG) | 750 | 1000 | 1500 | 2000 | 3000 |

| Min Capacity (KG) | 600 | 800 | 1200 | 1600 | 2500 |

| Heel (KG) | 250 | 300 | 400 | 500 | 700 |

| Max PourRate (molds/H) | ≤600 | ||||

| Temperature Loss (℃/min) | 1.5~3 | ||||

● Bottom type heated pouring furnace

Scope of application

The heated pouring machine has series resonance lF power and high-efficiency induction coil, power factor always better than 0.95, featuring accuracy molten temperature control and flexibility like unheated type pouring machine. Co-ordinating with high-end control system and removable base, providing perfect solution for grey iron and ductile iron etc foundry.

Advantages

- Dynamic automatic correction

- Patented heating induction coil

- Using the latest medium frequency power system technology

Specification

| Model | RKJH0.75 | RKJH1.0 | RKJH1.5 | RKJH2.0 | RKJH3.0 |

| Rated Capacity (KG) | 750 | 1000 | 1500 | 2000 | 3000 |

| Min Capacity (KG) | 600 | 800 | 1200 | 1600 | 2500 |

| Heel (KG) | 300 | 350 | 450 | 600 | 900 |

| Power (KW) | 150 | 200 | 250 | 280 | 300 |

| Heating Up (℃/min) | 12 | 12 | 12 | 10 | 8 |

| Max PourRate (Molds/H) | ≤600 | ||||

● Automatic pressurized pouring heating furnace

Scope of application

Rongke pressurized pouring heating furnace has been equipped with high-end lF power with power factor always better than 0.95 and automatic pressuring system with nitrogen protection. especially suitable for foundry occasions which need accurate temperature control and exact pouring control like iron, copper base.

Advantages

- Automatic control

- Nitrogen protection and pressurization

- Precise air pressure control

Specification

| Model | RKGH3.0 | RKGH4.0 | RKGH5.0 | RKGH6.0 | RKGH8.0 | RKGH10.0 |

| Rated Capacity (KG) | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Valid Capacity (KG) | 1800 | 2400 | 3000 | 3600 | 4800 | 6000 |

| Power (KW) | 250 | 300 | 400 | 500 | 600 | 700 |

| Heating Up (℃/min) | 6.2 | 5.5 | 6 | 6 | 5.5 | 5.2 |

| Max PourRate (mold/H) | ≤600 | |||||

| Heel | 40% | |||||

Control System

Rongke Automatic Pouring System advantages:

- The control system can achieve automatic,semi-automatic and manual pouring; Operator can optimize the pouring process in different method and storage them conveniently in mode pattern, which is callable when same pouring

pattern and editable before output to the pouring machine. - Storage of many menu is available, each menu can store multiple mode or pattern combination.

- The control system has power control function, information of the induction coil like voltage, current, power, phase angle, resistance, reactance can be displayed, consumption calculation and visualization help to simplify the monitor on the induction coil.

- The control system control the furnace inner pressure, pressure control is in linkage with the stopper rod to guarantee safety operation; Pressure and slot level is controlled automatically. All parameter settings including molten level, pressure limit, speed cureve etc can be set on the operator panel.

- The operating interface is in simple design, operator need only to touch on the screen for different operation, its smart and flexible diagnosis and trouble shooting tools kit would help to find the failure source and solve them quickly.

Vision System

In the moving of mold line, the vision system would detect approaching of the pouring cup and position above the cup, identify the cup size and position with visual pixel; once the pouring start, the camera would check the cup inner level by reflection; By the high contrast between the molten and molds, the reflection won’t be affected by the pouring current, assuring a constant level, no lack pouring or over pouring; After finish, the data would be stored for further optimization.

Stopper Rod System

Pouring machine stopper rod system is equipped with a pneumatic stopper rod system and manual manipulate control system.

The system along with the servo driven rod make the move very delicate & reliable, easy to maintain. The operator can change the stopper speed and servo motor status by adjusting the inverter. The stopper has buffer design to reduce wearing; System can be reset to zero position from its present position, the stopper has rotate function so when slag begin to stick it can rotate to remove the slag.

Inoculant System

The control system is connecting with the inoculant system, by combining the inoculant system into the control system, operator can control the whole inoculant process, A variable feeding speed inoculant device can store the inoculant speed as part of the production formula. When the pouring change, the inoculant speed would change accordingly, no risk of wrong inoculant (if possible, lower the speed to save inoculant material). The feedback would be received by the control system, based on the setting, the alarm would be sound and interrupt the pouring if necessary.