Furnace Industries: Pioneering Excellence in Thermal Solutions

The furnace industry is crucial across numerous sectors, delivering vital thermal solutions essential for modern industrial operations. Furnaces are central to processes like smelting and purifying both ferrous and non-ferrous metals, steelmaking, heat treatment, vacuum smelting, and powder metallurgy. Advanced furnace technologies enable precise temperature control and improved efficiency. Rongke, a leading OEM and ODM manufacturer, provides complete molten solutions designed for various industrial applications. Their products enhance the quality and efficiency of metal casting, silicon melting, and precious metals processing, ensuring top performance and sustainability.

Core Technologies and Innovations

Description of Pioneering Technologies Developed in Furnace Industries

The furnace industry has undergone significant technological advancements, enhancing efficiency, performance, and sustainability. Key innovations include high-efficiency furnaces that utilize advanced materials and designs to maximize thermal output while minimizing energy use. Additionally, state-of-the-art thermal management systems have been introduced to precisely regulate temperatures, thus improving product quality and reducing waste. Sustainable technologies, such as regenerative burners and waste heat recovery systems, further help in reducing the environmental impact of furnace operations.

1. High-Efficiency Furnaces

High-efficiency furnaces are engineered to optimize fuel utilization and lower emissions. Innovations in these furnaces include advanced insulation materials, precise temperature control systems, and improved combustion techniques. These advancements lead to reduced operational costs and a smaller environmental footprint, making high-efficiency furnaces essential for modern industrial applications.

2. Advanced Thermal Management Systems

Thermal management systems have evolved to offer precise temperature regulation, crucial for industries requiring exact thermal conditions. These systems deploy sophisticated sensors and control algorithms to maintain optimal temperatures, ensuring consistent product quality and reducing energy waste. They are particularly valuable in sectors such as semiconductor manufacturing and high-precision metallurgy.

3. Sustainable and Energy-Saving Technologies

Sustainability in furnace operations is achieved through technologies like regenerative burners that recycle waste heat to preheat incoming air, and advanced insulation materials that reduce heat loss. These innovations not only cut energy consumption but also lower greenhouse gas emissions, supporting global environmental goals.

Patents and Proprietary Technologies

The furnace industry is distinguished by numerous patents and proprietary technologies that provide a competitive edge. These patents often cover unique designs, advanced materials, and innovative control systems that enhance furnace performance and efficiency. Companies invest heavily in research and development to secure these advancements and maintain their market position.

Case Studies Showcasing Technology Implementation and Impact

Various case studies illustrate the benefits of advanced furnace technologies. For example, a steel manufacturer that integrated high-efficiency furnaces and regenerative burners reported a 20% reduction in energy use and a significant drop in emissions. Similarly, a semiconductor company improved both product yield and quality by adopting advanced thermal management systems, highlighting the tangible benefits of these technological innovations.

Industry Impact

Role in Shaping Thermal Solution Standards

The furnace industry is instrumental in establishing standards for thermal solutions. Through ongoing innovation and rigorous testing, industry leaders set benchmarks for efficiency, safety, and environmental performance. These standards are widely adopted, driving improvements across various industrial sectors.

Contributions to Energy Efficiency and Sustainability

Advancements in furnace technology significantly contribute to energy efficiency and sustainability. By developing solutions that lower energy consumption and emissions, the industry supports global efforts to address climate change, helping industries balance economic growth with environmental responsibility.

Partnerships and Collaborations with Other Industry Leaders

Collaborations between furnace manufacturers and other industry leaders foster technological innovation. These partnerships often involve joint research projects, shared technology platforms, and cooperative development of new solutions. Such collaborations expedite the adoption of cutting-edge technologies across different sectors.

Awards and Recognitions Received

The furnace industry has garnered numerous awards and recognitions for its technological contributions, efficiency improvements, and sustainability efforts. These accolades underscore the industry’s commitment to innovation and excellence, solidifying its role as a key player in modern industrial processes.

Rongke‘s Research and Development

Rongke IDE Full-Time and All-Round Furnace Leakage Alarm System

Rongke has introduced an advanced furnace leakage alarm system designed to enhance safety. This system detects molten iron seepage through a current detection electrode and triggers alarms to indicate specific locations, facilitating prompt intervention.

Leakage Detection Principle

The leakage detection system operates by sensing seepage of molten iron through gaps in the furnace lining. When molten iron contacts the current detection electrode, it triggers a leakage current alarm. If the leakage reaches the coil, a voltage detection circuit activates, providing alarms and identifying the exact location of the leak.

Grounding Alarm Detection Principle

The grounding alarm system detects leaks when molten iron is within 2 cm of the coil. If the leakage current to the ground surpasses set thresholds or coolant conductivity increases, the intelligent system activates an alarm, ensuring early detection and preventing major failures.

Leading Energy Saving and Repeatedly Pioneering

Rongke employs high-quality TU1 grade oxygen-free copper from Chinalco Luoyang Copper Co., Ltd., and uses cold extrusion techniques to create energy-efficient products. The incorporation of double coil technology further enhances product efficiency and performance.

Magnet Yoke Technology

Rongke’s magnet yoke is constructed from premium cold rolling directional silicon steel sheets, reducing magnetic loss and supporting the induction coil. The yoke features integrated cooling, ensuring balanced heat dissipation, extending the furnace’s operational life, and minimizing maintenance needs.

Rongke’s Global Presence and Market Influence

Expansion into Global Markets

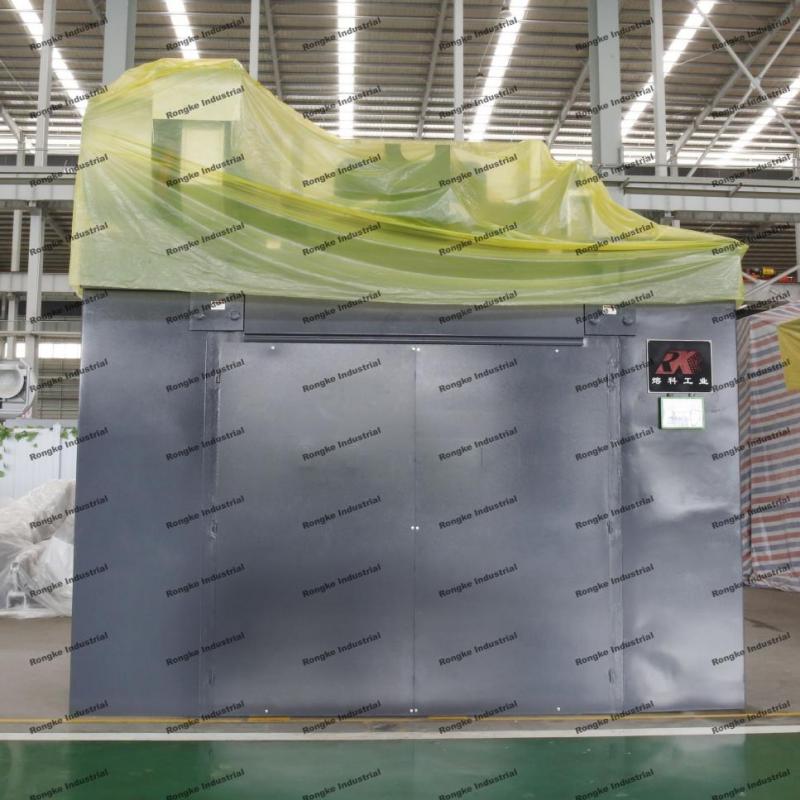

Rongke has established itself as a leading global provider of complete furnace systems. Their products are utilized in a range of industries, including ferrous and non-ferrous metal casting, steelmaking, heat treatment, electrolytic aluminum, vacuum smelting, powder metallurgy, silicon melting, and precious metals.

Adaptation to Different Market Needs and Regulatory Environments

Rongke’s success in international markets is due to its ability to adapt to diverse regulatory environments and market requirements. By understanding and complying with local regulations, Rongke ensures its products meet global standards while addressing specific industry needs.

Strategic Locations of Manufacturing and R&D Facilities Worldwide

Rongke strategically positions its manufacturing and R&D facilities across the globe to enhance production efficiency and innovation. This global presence allows Rongke to swiftly respond to market demands and sustain a competitive edge in the industry.

Corporate Social Responsibility and Sustainability

Initiatives in Environmental Sustainability

Rongke is dedicated to environmental sustainability through initiatives aimed at reducing energy use and emissions. Their products feature energy-saving technologies that align with global environmental objectives, contributing to a greener industrial future.

Community Engagement and Social Impact Projects

Rongke engages with local communities through various social impact initiatives, supporting community development, education, and environmental conservation. These efforts reflect Rongke’s commitment to corporate social responsibility.

Policies and Practices for Ethical Business Operations

Rongke upholds stringent ethical business practices, ensuring transparency, integrity, and accountability in all operations. Their policies promote fair labor practices, environmental stewardship, and ethical governance, fostering a culture of responsibility and trust.

Future Directions

Strategic Goals for the Next Decade

Rongke aims to lead the induction heating industry by focusing on safety, stability, energy conservation, and environmental protection. Their strategic goals include ongoing innovation, quality enhancement, and expanding their global market presence.

Emerging Markets and Technologies of Interest

Rongke is exploring emerging markets and technologies with significant growth potential. Areas of interest include renewable energy applications, advanced materials, and smart manufacturing solutions.

Long-Term Vision for Furnace Industries

Rongke envisions a future where the furnace industry leads in technological innovation, sustainability, and efficiency. Their long-term goal is to drive the industry towards a more sustainable and technologically advanced future, benefiting both the environment and global industries.

In Sum

The furnace industry, driven by innovative technologies and a commitment to sustainability, remains a vital component of modern industrial processes. Companies like Rongke are at the forefront, advancing technologies and setting new standards for efficiency and environmental responsibility. With a forward-looking vision and a robust global presence, Rongke is well-positioned to lead the industry towards continued innovation and sustainability.