SCR Intermediate Frequency Power Cabinet for Your Electric Furnace

The Needs and Solutions of Industrial Applications Using Electric Furnaces

Electric furnaces are at the heart of many industrial processes, especially in metallurgy, foundry and manufacturing. Precise temperature control is essential. As industries strive to minimize energy consumption, reduce operating costs and meet strict environmental regulations. The demand for energy-efficient, reliable and stable power systems is increasing. This has driven the development of advanced power cabinets, specifically designed to meet the unique needs of electric furnace operations.

One such solution is the SCR Intermediate Frequency Power Cabinet for Your Electric Furnace, which addresses the challenges faced by industries using electric furnaces. Guangdong Rongke Industrial Equipment Co., Ltd. is a leader in industrial power systems. Providing this state-of-the-art technology to improve the performance and efficiency of electric furnaces. This power cabinet provides continuous stability, energy-saving capabilities, and an innovative approach to ensuring safety and reliability.

SCR Intermediate Frequency Power Cabinet: A Game Changer for Your Electric Furnace

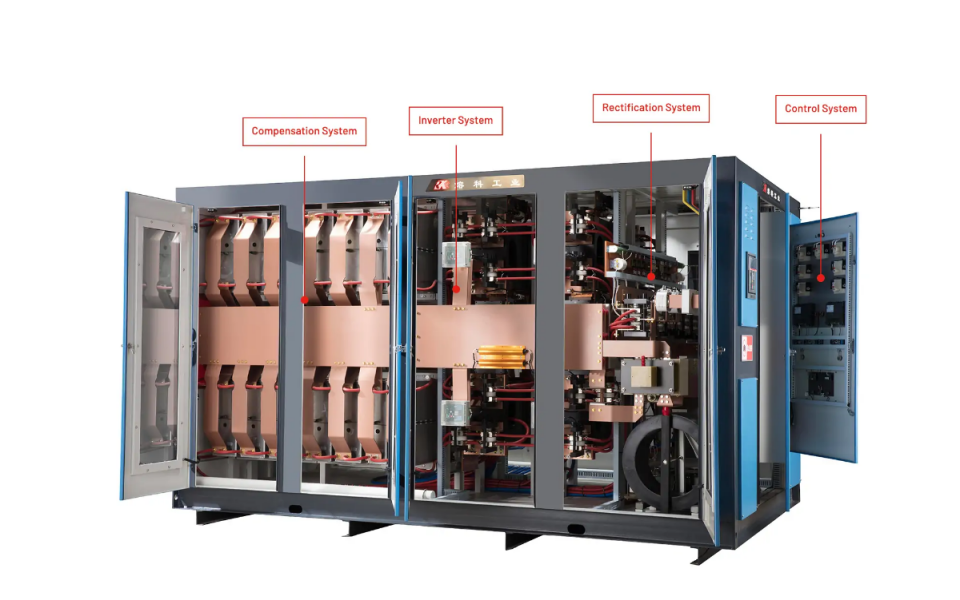

The SCR Intermediate Frequency Power Cabinet for Your Electric Furnace is engineered to solve the most pressing needs of electric furnace operations, from continuous power delivery to energy conservation. The cabinet features an advanced control system, rectification system, and inverter system, all working together to provide superior performance.

Three Systems for Continuous Stability

The SCR Intermediate Frequency Power Cabinet for Your Electric Furnace is built on three key systems: the control system, rectification system, and inverter system. Each of these components plays a crucial role in ensuring the continuous and stable operation of the electric furnace.

Control System: At the heart of the power cabinet lies the control system, which has been developed with independent intellectual property rights, including multiple patents. It utilizes international high-quality components, and patented furnace leakage protection (IDE) ensures the safe operation of the furnace. Moreover, the control system’s intelligent smelting operation keeps the system running smoothly and consistently, providing unparalleled safety and reliability.

Rectification System: The rectification system employs uncontrolled rectification technology combined with harmonic control technology. This unique combination enhances efficiency and safety while minimizing the risks associated with power surges and fluctuations. The patented isolating switch adds an extra layer of protection, ensuring stable power flow to the electric furnace.

Inverter System: The inverter system, built with high-quality international components, ensures that power is delivered efficiently and reliably to the furnace. It integrates both software and hardware linkage protection, providing smooth and stable operation throughout the smelting process.

Pursuit of Energy Saving: Reaching New Heights of Efficiency

In today’s energy-conscious world, reducing power consumption is a top priority for industries. The SCR Intermediate Frequency Power Cabinet takes energy efficiency to new levels, boasting a conversion efficiency of over 98%. This remarkable performance is achieved through innovative design and careful selection of components, resulting in lower energy consumption and higher operational efficiency.

Voltage Feedback Resonant Circuit: One of the key features that achieves this high efficiency is the unique voltage feedback series resonant circuit design. This enables the system to optimize power conversion. This reduces energy waste and ensures the furnace operates at peak efficiency.

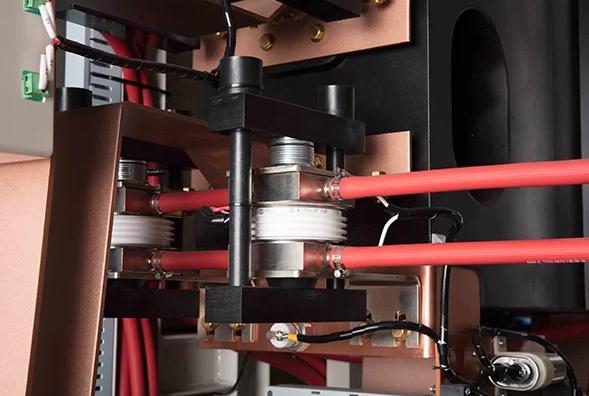

High-Quality Components: Every component within the power cabinet is carefully selected to ensure minimal energy loss. The copper bars and tubes, sourced from well-known domestic brands, undergo sandblasting and passivation processes to enhance conduction efficiency. Even details such as the use of copper screws to secure the copper bars are optimized for energy savings.

System Matching: The careful matching of system components further enhances energy efficiency. The layout of the power cabinet is designed to optimize the conduction of electricity, reducing heat loss and improving overall energy performance.

Stable and Continuous: Hardware and Software Linkage with Multiple Protections

In the industrial environment, reliability is paramount. The SCR Intermediate Frequency Power Cabinet for Your Electric Furnace excels in providing a stable and continuous power supply through the seamless linkage of its hardware and software systems. Multiple layers of protection ensure that the system remains safe and functional even under the most demanding conditions.

Comprehensive Software and Hardware Protection: The advanced software and hardware linkage within the power cabinet ensures that any potential faults are detected and addressed swiftly. This reduces downtime and enhances the reliability of the electric furnace.

Sound Insulation Technology:One of the most innovative features of the SCR medium frequency power cabinet is its industry-leading sound insulation. Noise from electrical cabinets has long been a problem in industrial environments. But Rongke’s R&D team took the lead in proposing a solution that can greatly reduce operating noise. Make the operator’s working environment more comfortable and safer.

Safety Above All: The SCR Intermediate Frequency Power Cabinet is equipped with the safest and most reliable control system available. Its patented furnace leakage protection technology (IDE) ensures that any potential issues are mitigated before they become significant problems. This focus on safety provides peace of mind to operators and reduces the risk of accidents.

First-Class Manufacturing Technology and Components

The SCR Intermediate Frequency Power Cabinet reflects Guangdong Rongke Industrial Equipment Co., Ltd.’s commitment to quality. The company adheres to the ISO quality management system, ensuring that every stage of production—from design to manufacturing—is held to the highest standards.

Rigorous Component Selection: To guarantee the stability and reliability of the equipment, only internationally recognized brands are used for core components. The supplier assessment system implemented by Rongke ensures that all components meet the strictest quality standards.

Meticulous Attention to Detail: Every member of the Rongke team participates in the quality control process. From self-inspection during production to post-installation testing, no detail is overlooked. This level of care ensures that the power cabinet operates reliably and safely over its lifespan.

Creating New Standards in Energy Efficiency and Reliability

The SCR Intermediate Frequency Power Cabinet for Your Electric Furnace from Guangdong Rongke Industrial Equipment Co., Ltd. represents a significant advancement in electric furnace technology. With a conversion efficiency of over 98%, it sets a new standard for energy savings in industrial applications. Innovative design and selection of high-quality components, coupled with powerful control systems and sound insulation technology. Making this power cabinet ideal for any industry that relies on electric stoves.

The key to the success of this power cabinet lies in its attention to detail. From copper busbar layout to the implementation of advanced control technology, Rongke pays attention to every aspect of the design. It creates products with unparalleled performance and reliability. This dedication to detail and quality has won the trust of customers and put it in a leading position in the industry.

Conclusion

In conclusion, the SCR Intermediate Frequency Power Cabinet for Your Electric Furnace is more than just a power system for electric furnaces—it is a comprehensive solution designed to meet the evolving needs of modern industry. By offering continuous stability, energy savings, and multiple layers of protection, this power cabinet helps industries achieve their operational goals while minimizing energy consumption and ensuring safe, reliable performance.