Induction Furnace for Steel Melting: Efficient and Modern Solutions

Steel melting plays a crucial role in various industries because steel is a key component in buildings, machines, and tools. To achieve steel that is both pure and robust, the melting process must be carefully controlled and efficient.

One modern method for melting steel is through the use of an Intermediate Frequency Coreless Induction Furnace (IFCIF). This furnace generates heat using electricity, melting the steel quickly and uniformly. As a result, it has become a popular choice in factories, offering significant improvements over traditional methods by saving both energy and time.

In today’s fast-paced industrial environment, efficient and rapid steel production is essential. The IFCIF not only speeds up the process but also facilitates the recycling of scrap metal, benefiting the environment and reducing costs. So, how exactly does this furnace work? Let’s take a closer look.

Challenges of Steel Melting

Steel melting is important for many industries. However, the process has some challenges. One problem is high energy use. Melting steel needs a lot of heat. Many factories use electricity or fuel to create this heat. But energy costs are high. This makes steel production expensive.

Raw Material Impurities

Another challenge is impurities in raw materials. Scrap metal is often used to make new steel. But it may have dirt or unwanted metals. These impurities can make the steel weak. So, factories must clean the metal before melting it. This takes extra time and effort.

Furnace Maintenance

Furnace maintenance is also a problem. The high heat inside the furnace can damage its walls. If the furnace is not in good condition, it may not work well. Repairs take time and cost money.

What is an Intermediate Frequency Coreless Induction Furnace?

Definition and Working Principle of Induction Furnaces

An Intermediate Frequency Coreless Induction Furnace (IFCIF) is a special type of furnace used to melt steel. It works by using electricity to generate heat. The furnace does not need direct burning of fuel. Instead, it uses an electromagnetic field to heat the metal inside. This process is fast and efficient.

The body of the furnace has many interactive windows. It is made with high-quality materials and advanced technology. The design ensures safety, stability, and energy efficiency. The furnace is built with strong materials, and its processing technology is advanced. This makes the production process safer and more reliable. It also reduces energy use and improves performance.

What is the Innovation of Rongke?

Rongke has developed new safety and alarm systems to improve furnace performance. One of these is the IDE full-time and all-round furnace leakage alarm system. This system helps detect leaks early, preventing accidents and equipment damage.

Leakage Detection Principle

Molten metal can seep through small gaps in the furnace lining. When it touches a current detection electrode, the system detects a leakage current and triggers an alarm. If the molten metal reaches the coil, the voltage detection circuit activates an alarm. It also shows the exact location of the leak.

Grounding Alarm Detection Principle

If molten iron gets 2 cm close to the coil, the system measures the leakage current. If the current goes beyond the set limit, the system automatically triggers an alarm. It also checks the conductivity of the coolant. If the conductivity is too high, the system detects the issue and activates an alarm. This helps prevent serious furnace damage.

Advantages of Rongke Induction Furnaces in Steel Melting

Fully Enclosed Steel Furnace Shell

The furnace body has a strong and fully enclosed design. It follows international standards for strength and durability. The welding process uses advanced technology to ensure tight sealing. This prevents powder leakage and reduces magnetic radiation.

The enclosed design provides many benefits:

- Higher safety and reliability

- Better strength and rigidity

- Lower noise levels

- Easier maintenance

This makes the furnace more efficient and long-lasting.

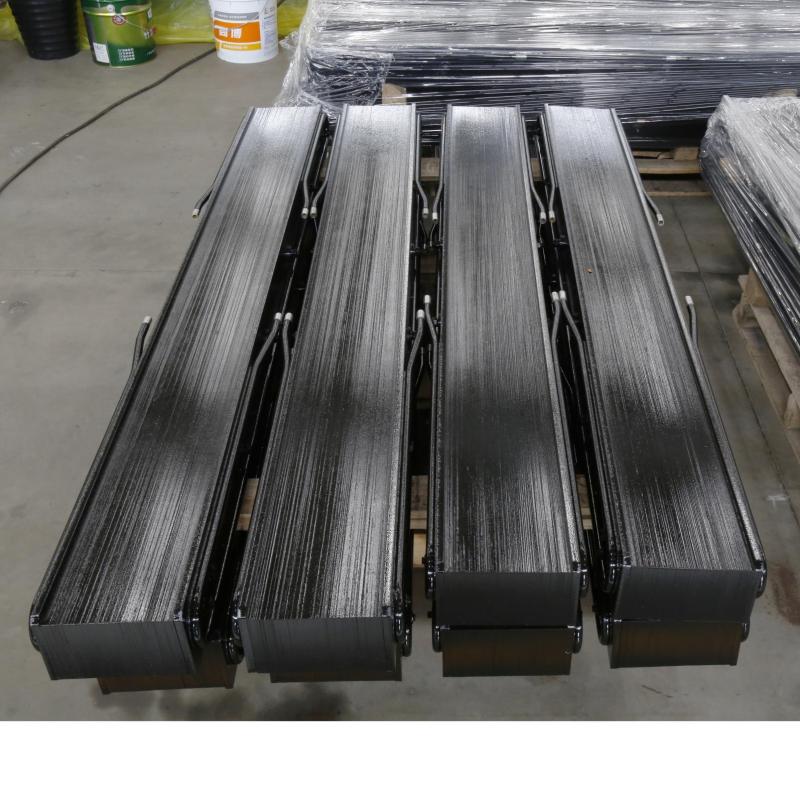

High-Quality Induction Coil

The induction coil is the most important part of the furnace. Rongke uses TU1 grade oxygen-free copper from Chinalco Luoyang Copper Co., Ltd. This material ensures high conductivity and durability.

The coil is made using the cold extrusion process, which creates the thickest copper tubes in the industry. Rongke also uses double coil technology. This helps the furnace work more efficiently and with lower energy consumption.

Advanced Magnet Yoke Technology

The magnet yoke is made of high-quality cold-rolled silicon steel sheets. This material reduces magnetic loss to less than 105. The coverage rate of the magnet yoke is higher than 70%, which improves furnace performance.

The magnet yoke supports the induction coil from all sides. It also directs the magnetic field to the molten metal, improving melting efficiency. Water flows through both sides of the magnet yoke, ensuring even heat dissipation. This improves the working life of the furnace.

The cooling function and support function are combined. This makes the magnet yoke maintenance-free. Using high-quality silicon steel sheets and an advanced design reduces heat loss and increases durability.

Why Choose Rongke?

Certified and Trusted Industry Leader

Rongke was the first in the industry to achieve important certifications. The company passed the EU CE certification and the ISO quality management system certification. These certifications prove that Rongke meets high safety and quality standards. The company is also recognized as a high-tech enterprise.

Award-Winning Reputation

Rongke has received many honorary titles for its quality and service. Some of these include:

- “Quality, Service, and Reputation AAA Enterprise”

- “Contract-Abiding and Trustworthy Enterprise”

- “Low-Carbon Environmental Protection and Energy-Saving Innovation Brand”

- “National Authoritative Testing. Quality Qualified Products”

These awards show that Rongke is trusted by customers and experts. The company focuses on delivering reliable and energy-efficient products.

Customer-Focused Approach

Rongke understands what customers need today and in the future. The company listens to customers and improves its products. It provides high-quality service and long-lasting solutions. Rongke aims to meet customer expectations and go beyond them. Many industries choose Rongke because of its commitment to innovation and customer satisfaction.

Applications in Steel Manufacturing & Beyond

Rongke induction furnaces are used in many industries. They play a key role in steel production and metal recycling.

Foundries and Steel Plants

Many foundries and steel plants use Rongke furnaces. They help produce high-quality steel for different applications. The furnaces work fast and efficiently, making them an ideal choice for modern factories.

Automotive and Aerospace Industries

Steel is an important material in the automotive and aerospace industries. Rongke furnaces help make strong and durable metal parts. These industries need precise and high-quality metal. Rongke’s technology ensures consistent steel production.

Recycling and Sustainable Metal Production

Recycling is important for sustainability. Rongke furnaces help melt scrap metal into new steel. This process reduces waste and production costs. It also helps protect the environment by using less energy.

Recycling metal with induction furnaces is better than traditional methods. It produces less pollution and saves resources. Many companies choose Rongke furnaces for eco-friendly production.

Choose Rongke for Better Steel Melting!

Rongke makes high-quality induction furnaces. The company follows strict safety and quality standards. It has earned top industry certifications. Many businesses trust Rongke for its strong and reliable products.

Rongke has won awards for its excellent service. It provides energy-saving and eco-friendly solutions. Customers get durable and efficient furnaces. The company always improves its technology. It listens to customer needs and delivers the best results.

Upgrade your steel production with Rongke. Choose the best furnace for your industry. Contact us today!