Best Automatic Feeding System Manufacturers for Efficient Farm Automation

Precision Control in Automatic Feeding Systems: An Approach to Perfection

For a large scale manufacturing industry or the agricultural sector the feeding system forms the base where automation and precision is of paramount importance. Automatic Feeding System Manufacturers have gone a step further to develop systems that will bring efficiency in producing quality products with minimal human intervention. The characteristic feature for these systems is the permissible degree of accuracy that needs to be reached when batch (or portion) controlling both the initial materials and reagents. Automated feeding systems use radar scanning, electromagnetic control and smart sensors that have transformed industries such as animal farming, metal processing among others.

Why is precision accuracy control important in automatic feeding system?

In automatic feeding systems, accuracy is achieved hence the required quantity and type of raw material is fed in at the right time, boosting the operations’ precision. These systems can be flexible and could evaluate production requirements appropriately, making certain that the correct equilibrium between ingredients and raw materials is achieved at all times. Therefore, any manufacturing industry, or livestock feeding systems, has an easy process that enhances the production process with automatic feeding systems.

How Automatic Feeding Systems Work: The Key Components

These systems have many parts that make them effective feed deliverance systems for optimal feeding. Here’s an overview of some of the essential elements:

Radar Scanning Technology

Radar scanning technology is one of the main instruments used in precision control. In Automatic Feeding System Manufacturers, radar systems capture in real time the position of raw materials. By tracking the movement of the materials it is possible to optimize the system to get the required batching. This makes it possible to feed the process with the right quantity of ingredients as without delay as is possible.

Automatic Travel Crane and Electromagnetic Disc Co-ordination

In feeding systems, automatic travel cranes with disk electromagnetic features facilitate the standard movements and dispensing of the supplies. This coordination is specially useful in industries that lay with heavy materials like a steel melting operation in which the feeding of raw material must be accurate and on timely basis.

The travel crane transports the material into position with high precision while the electromagnetic disc controls the rate of flow to create the desired mixture. Such automation reduces manual intervention, cutting down the possibilities of human error which is not good, especially in areas of high demand.

Alloy feeding and adjustment of the chemical composition

In many industries such as metallurgy, it is important to be able to determine the feeding amount of the alloy very accurately. Trolley Charging Systems can determine the alloying content depending on the material and the Grade of metal being manufactured. These systems interface with devices, such as spectrum analyzers, to enable changes to the batching ratio so that the molten metal is perfect. The accurate batching silos erected above furnace ensure that on the spot adjustments can be made on the molten composition. This process ensures highest quality of the products and minimum wastage hence automatic feeding systems plays an important role for industries which needs accurate feeding of material.

Advantages of Automatic Feeding Systems: The Key Benefits

Less Raw Material Waste

Another advantage of such a system is that it decreases the wastage of raw materials. It for example exposes the common traditional ways of manual feeding as being more prone to errors in that extra material is always added hence unnecessary costs. Automatic systems utilize sensors to precisely measure the volume of material to be added and eliminate additional portions hence increasing sustainability.

Real Time Processing and Intelligent

Adapting From the fully automated feeding system feeding to the exact proportions, a function that batched material and smelting process, as well as tracking the state of the loops ingredients in real time. It is due to this that operators are capable of making intelligently adjustments to equal feedback from the system to balance the process without interference. Real time data management allows the system to correct feed rates and avoid operational problems based on the evolving conditions.

Flexible for Special Requirements

Every industrial process is unique, and thus, the automatic feeding system is unique in design to meet particular needs of a client. These systems may be made according to varieties of ingredient blending or production requirements. Providers can develop feeding schedule, modify recipes, and evaluate outcome to guarantee that the system satisfies the need of the facility.

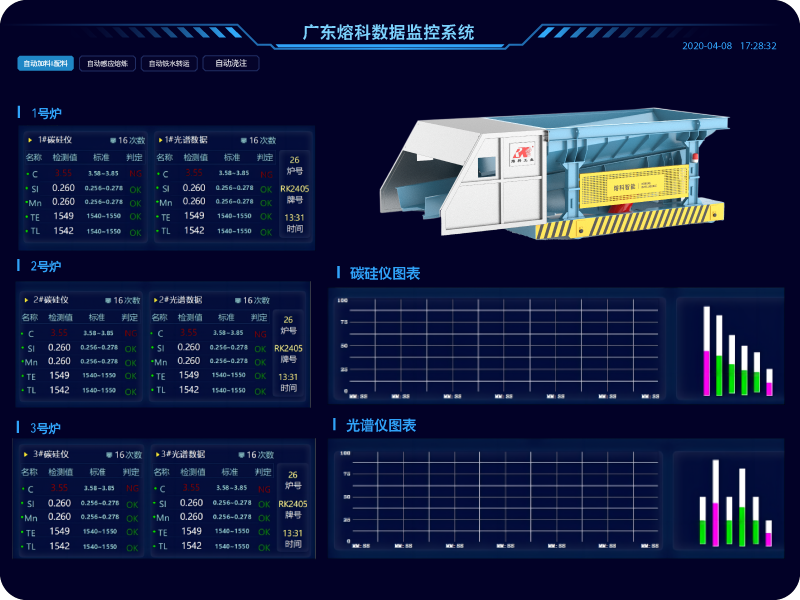

Rongke: An Automatic Feeding System Industry Innovator

Rongke Group is an Automatic Feeding System Manufacturers that has been dedicated in the process of the establishment of sophisticated feeding solutions. We are proud to offer our clients exceptional feeding systems which consumer’s requirements of a specific industry such as metal smelting, agriculture, and livestock among others.

At Rongke we ensure that all the business activities are controlled for customer focus and quality. We operate on the mission of advocating for safety, stability, energy efficiency as well as conservations in the field of induction heating and melting. Our strong commitment is to offer creative ideas that translate into positive results in our clients’ processes and responsible development of technologies with and for the planet. Rongke has brought experienced and professional team and technological advancement in automatic feeding systems to meet the requirements of precision control, real time monitoring, and individualistic requirements for batching of materials. Animal feeding equipment, fish farming equipment, or industrial batching equipment are available, which not only enhances operation efficiency and final product quality.

Automatic Feeding System Brands

Therefore, if you need Automatic Feeding System manufacturers, Rongke Group would be your best choice. Specializing in farm automation technologies, Rongke has a full line of automatic feeders to accommodate different kinds of production animals and aquaculture: automatic poultry feeders, automatic pig feeders, and fish feeders. Those sorts are created as for managing the farm operations, for enhancing the health of the stock and for feeding the animals with maximum accuracy while incurring minimum wastage.

- We believe at Rongke that a technical solution that dynamically improves productivity of operations and provides animals with wholesome nutrition is attainable. So, whether you are in the poultry farming business, swine farming business or in the aquaculture farming business, we have designed an automatic feeding system for your use.

- The team comprises engineers, and skilled operators with profound knowledge of operational processes of medium-frequency induction melting furnaces. Preparing the raw material, as well as constantly monitoring and regulating furnaces, our team guarantees effective and highly quality production services. Having years of experience, we are confident that each existing furnace is running at its best, producing top-quality work during each run.

Conclusion

The future of automatic feeding systems looks promising, with more industries adopting advanced technologies that offer precision and efficiency. From smart sensors and intelligent adjustments to customized batching formulas, these systems are driving innovation across various sectors. By choosing a reliable and forward-thinking manufacturer like Rongke Group, businesses can ensure they are staying ahead of the curve in the increasingly competitive global marketplace.