Precision Control

Automatic Iron batching

The system can automatically generate the best batching proportion based on the production demand and the raw materials’composition, the radar will scan the raw materials’ position then by the close coordination of automatic travel crane&electromagnetic disc achieving the automatic iron batching.

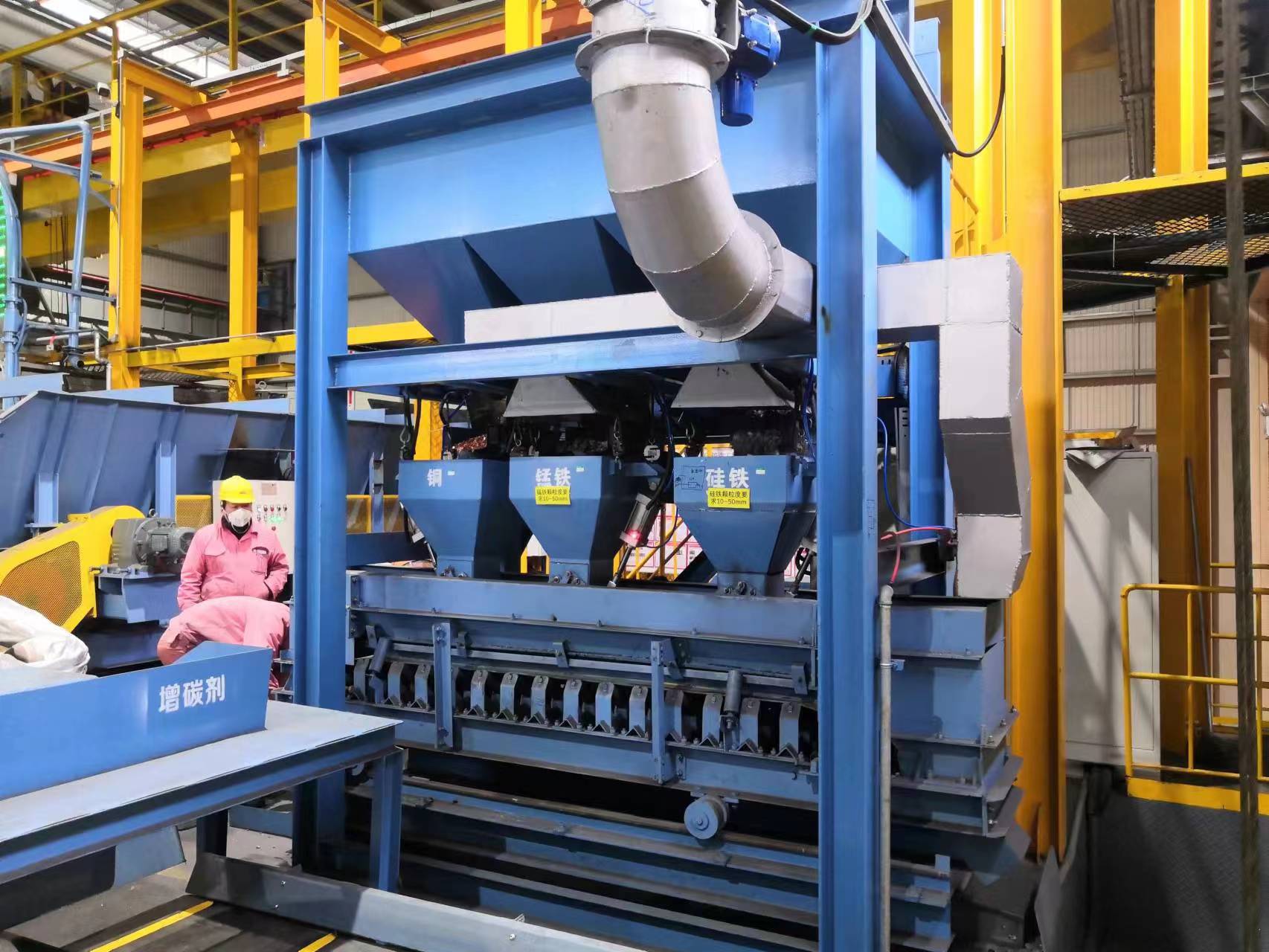

Alloy batching

The amount of alloy added is calculated based on the raw material composition and the grade to be produced; and it can be linked with the spectrum to correct and optimize the batching plan in real time; it effectively reduces the amount of alloy used while ensuring the chemical composition of the molten iron.

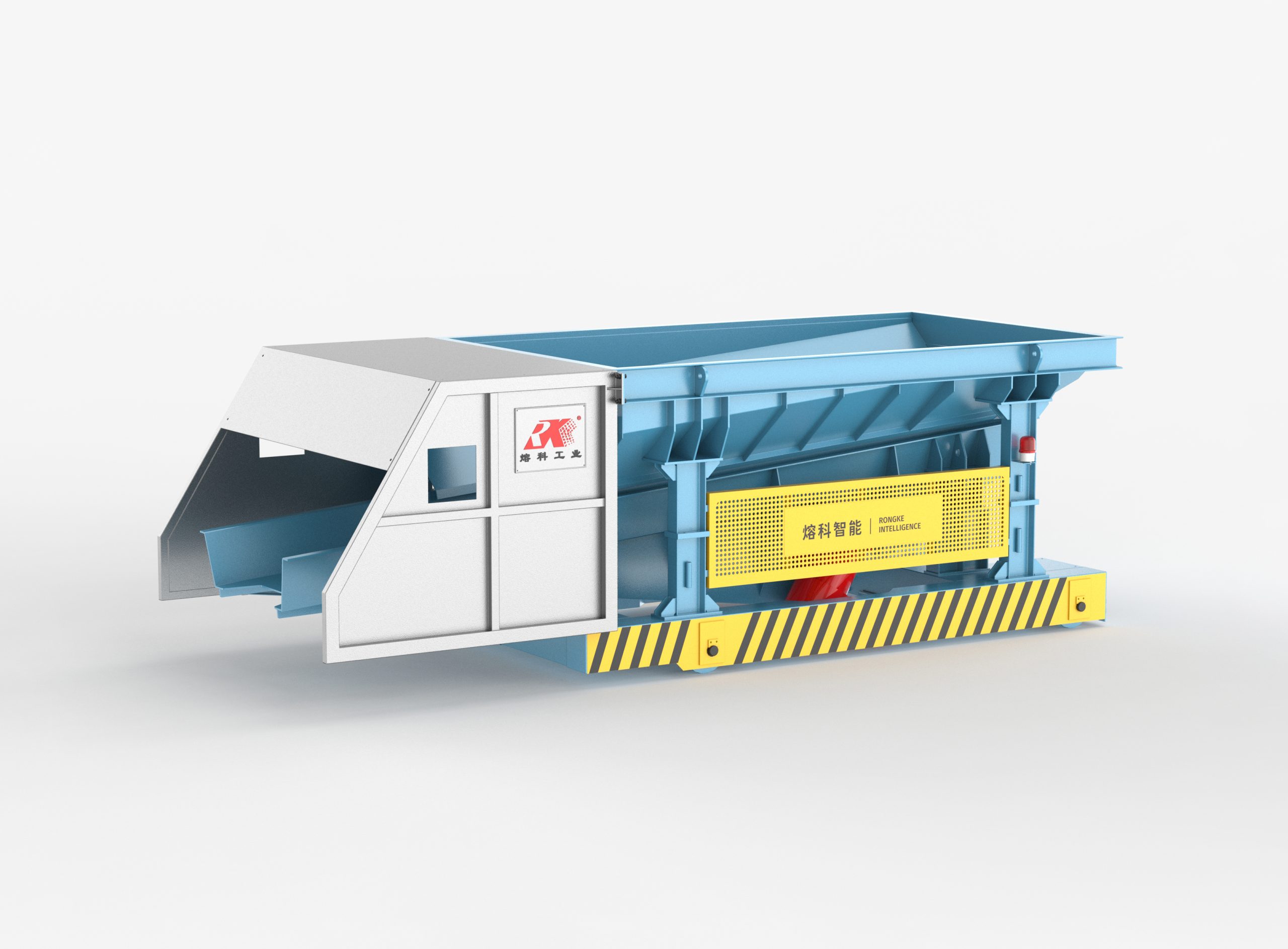

Charging Cart

The vibration charging cart is designed with independent alloy bin and iron batching bin, which can control the charging sequence; at the same time, it can be linked with the batching system and melting furnace in real time to realize automatic or semi-automatic charging.

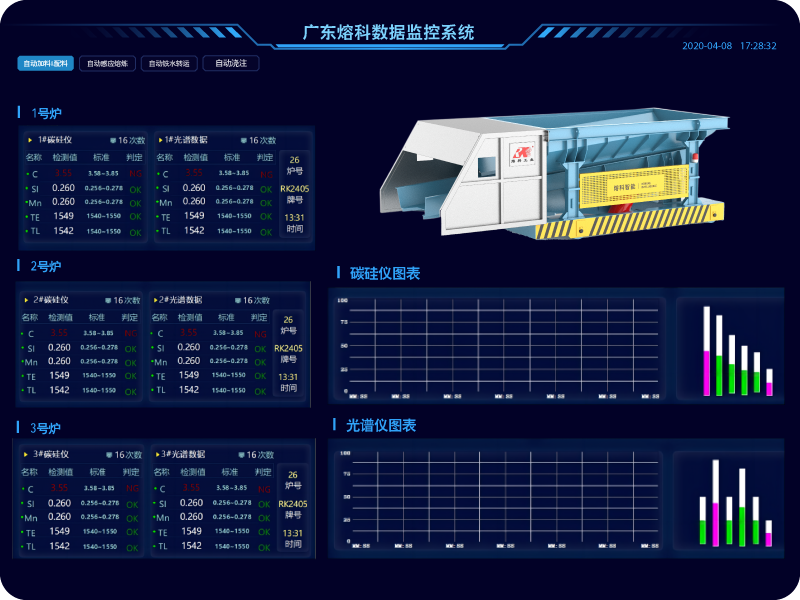

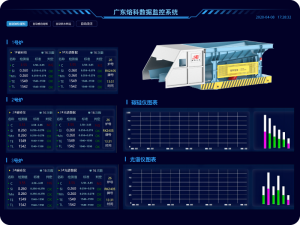

Real-time monitoring

The system can monitor the charging and batching status of the smelting process in real time, and intelligently optimize the charging and batching plan based on the feedback information, ensuring the advantages of less labor in the entire smelting process, low labor intensity of workers, high charging efficiency, saving alloy and electricity costs, high safety and low risk.

Advantage of Automatic Batching & Charging System

| Basic Info. | |||

| Model NO. | ODM | Type | Trademark |

| GD-RK-C-B&C system | OEM | Industrial | Rongke |

| Fuel | Casting | Brand | Origin |

| Electronic | Batching&Charging | Customized | China |

| Range of Applications | Transport Package | Working Type | Production Capacity |

| Industrial | Foam | Automatic | 20 |

- Adopts advanced sensors and control systems, which can accurately control the amount of raw materials added, ensure the accuracy of the batching process, and avoid the problem of waste and shortage of raw materials.

- Can monitor the smelting process and ingredient status in real time, and make intelligent adjustments based on feedback information to ensure the smooth progress of the entire smelting process.

- Can be customized on-site according to customer needs.

- Can batch based on the pre-set or stored formula automatically and upload these data to the computer, achieving the real time data management, which also help to facilitate the on site composition analyzing and optimizing the melting processing.

- Can calculate the alloy’s feeding quantity based on the material composition and the grade of metal to be produced. it can also interchange with the Spectrum Analyzer to modify and optimize the batching ratio; the accurate batching silo above the furnace can help to adjust the molten composition. All batching solution would be stored real-time into the batching system.

Straight-travel vibrating charging cart, it features good rigidity and high strength & long life-span. Starting, operation and stop can be managed easily and accurately, make the feeding easy in face of different material feeding demand. The cart can feed stably, no molten splash.